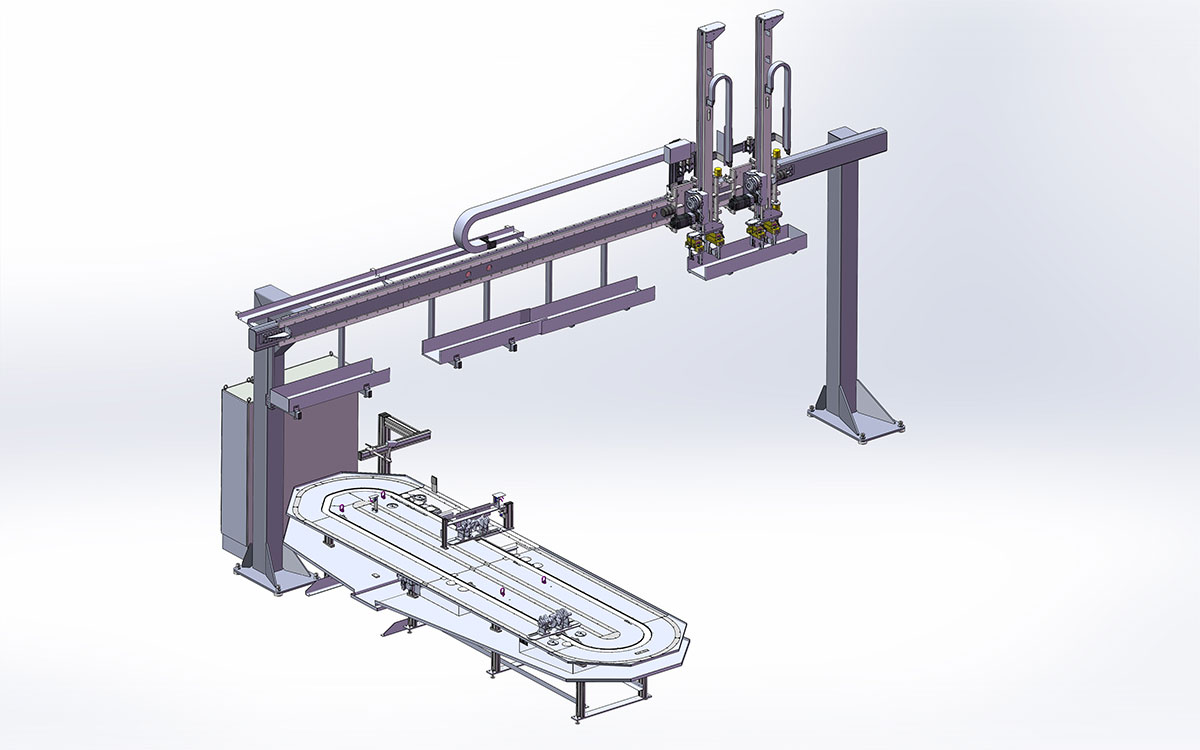

KBH linear NC reloaders are characterised by stability and strength. The 2010 series is used for workpieces, such as transmission shafts up to a weight of 10 kg. The 250 series is for particularly heavy workpieces, e.g. crankshafts up to a weight of 30 kg for passenger cars, or assembly components for trucks.

Video Gantry Loader

Video KBH gantry loading

The reinforced special structure of a reloader makes it possible to deliver the heaviest workpieces up to a weight of 150 kg directly into a machine tool, and then unload after machining.

Configuration variants are, among other things, independent travelling trucks, H-reloaders with two vertical axes, double grippers with swing head, upper transfer with combined travelling truck, and fitting with several independently-driven trucks.

Gantry loader for loading and unloading workpieces from machining centres in automation.