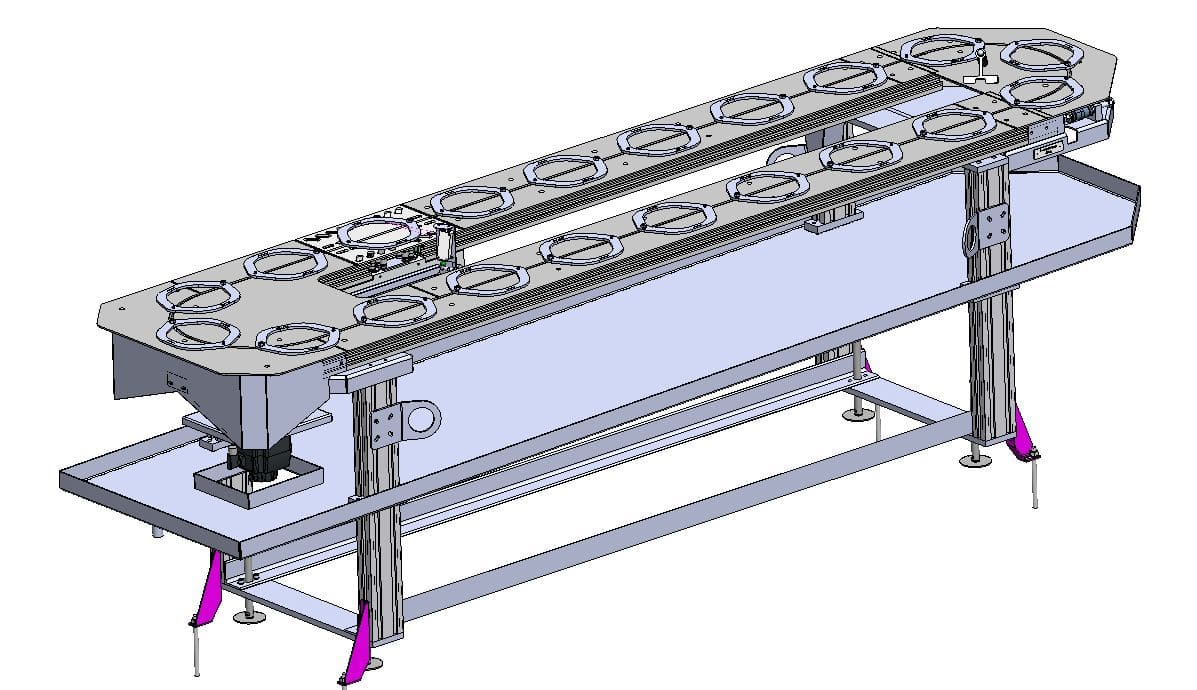

This is a transport system with open frames, serving to transport and quickly change workpieces in the automation of machining centres. Both rotationally symmetrical parts and parts of almost any form of envelope can be transported. Thanks to the NC-drive, the accuracy of part positioning is approx. 0.3 mm.

The transport of a workpiece is carried out by means of a chain with hollow pins into which drag frames are hung. Drag frames are mostly mounted manually. Finished workpieces can be taken from the transport system during a machining process.

The KBH drag frame belt can be designed in various versions and dimensions.