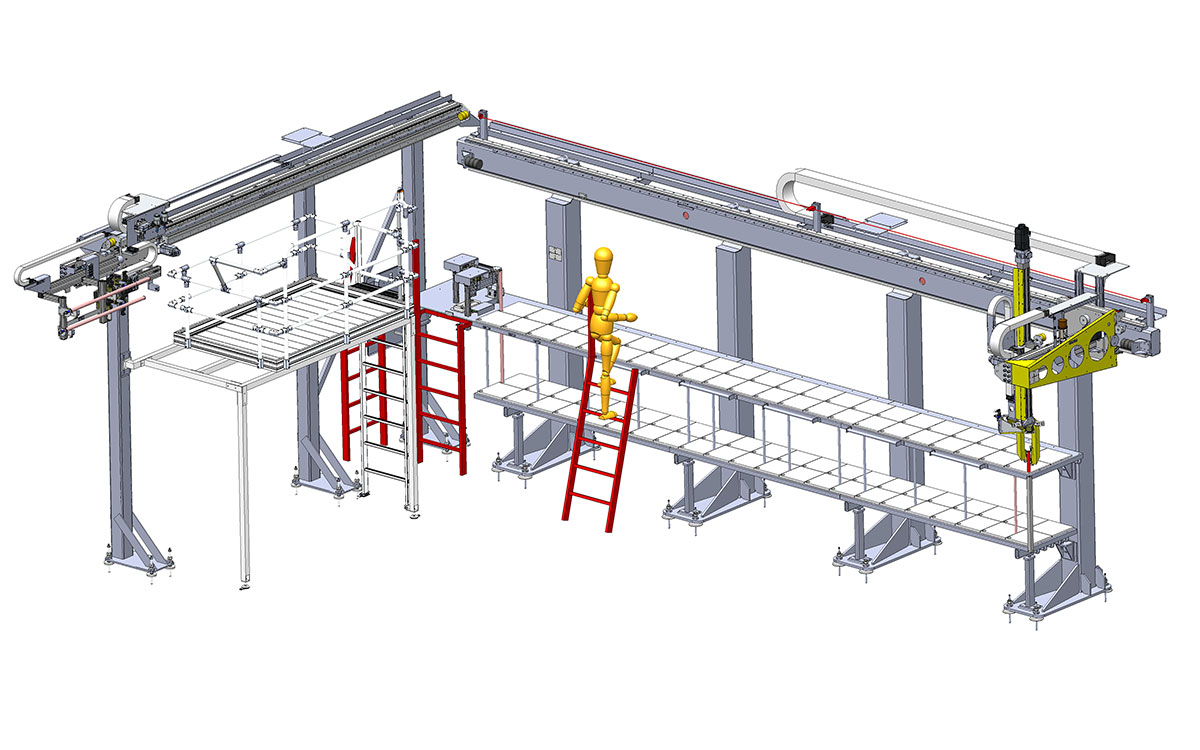

This workpiece buffer was specially developed for shafts, which can buffer a large number of round workpieces in a compressed space. Here, the shafts are deposited and stored vertically, but conveyed horizontally to the transfer point. In the discharge area, a robot then takes over the provided shafts and transfers them to the next machining process. In this example, a shaft storage system was developed that provides a storage capacity of 1500 workpieces.

Workpiece buffer for shafts - automation

By using workpiece storage systems, unplanned downtimes or disruptions in the production process can be bridged and cushioned without the material flow coming to a standstill. We at KBH design and manufacture well thought-out storage solutions for various industries and areas of application. Above all, the solid construction of our systems, with the aim of guaranteeing trouble-free use for our customers, is what sets us apart.

The KBH shaft storage system can be designed in various versions and dimensions. It is the optimum buffer for round parts that are to be temporarily stored in larger quantities.